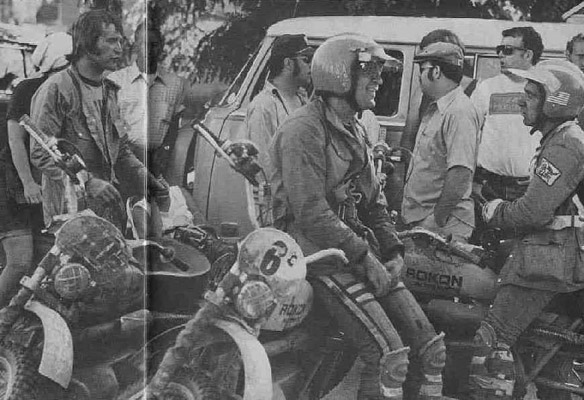

This is #232, Jim Fogle. He won a Bronze riding on the Rokon team.

This is #232, Jim Fogle. He won a Bronze riding on the Rokon

team.

This is yours truly. I don't remember where on the course I took this

one, but it had to be the day it didn't rain.

List of preparation work to be done on the Rokon for the 1975 ISDT in England:

1. Dome the rear brake piston - reduces heat transfer to the brake fluid, and allows the brake pad to pivot as needed. (Rectangular brake pad style)

2. Quick detach torque convertor dzus fasteners on the cover, can be removed with screwdriver.

3. Quick detach (QD) rear driven convertor clip instead of the 916" head bolt. Install a bolt with head machined off in lathe, drill hole for quick detach angel clip.

4. QD tool pack fasteners from Hi- Point boots.

5. QD fork pinch bolts

6. Rubber guide ring for throttle cables near lower front of gas tank.

7. Velcro attached flap on torque converter cover, in front to keep mud and water out.

8. Spare carb needle clip duct taped to air box on right side of bike, in case you drop original.

9. Spare left side footpeg with nut and bolt.

10. WM-1 Sun Wheel (brand) front rim with front axle welded with short lever handle (4")

11. Plastic lexan shield protecting headlight bulb.

12. Rider's wrench kept on left side crash guard with rubber bands.

13. Pouch behind right side number plast holding miniature air bottle and tire irons, number plate secured with pivot and dzus fastener.

14. Cut down front sprocket guard and silicone it in place as backup to bolts.

15. Slot the screws on the float bowl cover for straight screwdriver

16. Slot the front carb clamp screw for straight screwdriver.

17. Tape spare muffler stud nut on frame behind seat, and use silicone on stud nut on the muffler.

18. Miniature can of dri-slide or sewing machine oil for throttle cable maintenance.

19. 1.5" extra foam padding under original seal foam.

20. Long wire ties stored on the front number plate (feed into the wire ties holding the number plate on.

21. Cut down screwdriver stored in steering stem hole and secured with rubber band.

22. Time card holder with plastic checkpoint times window, and storage for wire ties.

23. Painted valve stem areas with bright red paint for easy location of valve stem when checking air or chaing flats.

24. Replace top half of Preston Petty numberplate/headlight combination unit with regular number plate (which is more flexible and won't break)

25. Modify drive torque Convertor bolt so the hex size matches the rear axle nut and can use rider's wrench on it. (15/16")

26. Drill and tap the front hub with 3/8-24 thread for quick detach bolts to be run through brake discs. This saves time if disc has to be changed, rather than having to use a ratchet and a 9/16" wrench fed into the spokes to hold the nuts.

27. Pop rivets in rear rim to help hold tire edge in place when low tire pressure. Drill hole for rim lock.

28. Duct tape inside of the Sun Wheel spoked wheel - two layers.

29. Antiseize solution on the threads of the chain adusters.

30. Water baffle cup and shield on the pull starter area.

31. Double thickness steel head-steady bracket, mig welded, loctited on mating surfaces when bolted to engine and frame.

32. Can of LPS25 spary for the ignition, or "ESP" spray.

33. Drilled and tapped spare screw and hole in the brake backing plates.

34. Modify bolt that holds rotomolded gas tank on by slotting it for screwdriver.

35. Grease fittings installed in the front brake pivot area

36. Install Malcolm Smith 6" rise handelbars - solid aluaminum.

37. Radius the handlebar clamps with rat-tail file where the handlebars might be stressed over time.

38. Install plastic box (Rubbermaid tupperware type) from store in the leather tool pack.

39. Friction tape under the grips, install with contact spray.

40. Spare rear axle nut taped to frame.

41. Lodge brand spark plug cap, siliconed in place.

42. Rubber flap around spark plug to minimize mud buildup around spark plug.

43. Cut down front brake lever length so won't break on crashing.

44. Extra carb needle taped on air box.

45. 13 tooth front sprocket Use "O-ring" Chain Gang chain.

46. Insert Filtron foam strips under the fork tube wipers, use Husqvarna fork boots over all.

47. 16 lb. Pencil tire gauge, from Rokon Trailbreaker stuff.

48. Never-seize the fork pinch bolts in the triple clamp area.

49. Break in the spare chain for replacement later in race.

50. Dri-slide treat the throttle cable and the spare, and tape spare parallel with original.

51. Duct tape top of downtubes to prevent mud splatter onto cylinder head of engine.

52. Spare kill button spring taped to handlebar.

53. Install vent tube on the rear brake master cylinder cover to prevent mud entry, shaped to prevent water and mud entry.

54. Install air valves atop forks, 14 psi.

55. Store rubber bands on fork steering stops.

56. 300-21 spare inner tube on bike behind seat. Spare drive belt located around headlight. Kawasaki compressed air bottles in tool pack.

Jim Hollander added: It looks like it may be Jim Fogle on the left.

"I

just learned of your rokonworld website and am fascinated by it.

I have saved 4 Rokons from 1975-1976 and obtained the only 501cc

Rokon the factory (actually a fellow out in the mid-west built

it for the factory) ever built, the 501cc Maico top end, gas tank

below the seat, air intake under the false gas tank shape, countershaft

sprocket in line with the swing arm pivot point so no chain slack changes

while suspension works, hand built frame, etc. I have recently acquired

a digital camera and when I get the hang of the digital I can make JPEGs

of the bike if RT-340 owners are interested. The other interesting

Rokon I saved is my 1976 ISDT gold medal bike from Austria."

"I

just learned of your rokonworld website and am fascinated by it.

I have saved 4 Rokons from 1975-1976 and obtained the only 501cc

Rokon the factory (actually a fellow out in the mid-west built

it for the factory) ever built, the 501cc Maico top end, gas tank

below the seat, air intake under the false gas tank shape, countershaft

sprocket in line with the swing arm pivot point so no chain slack changes

while suspension works, hand built frame, etc. I have recently acquired

a digital camera and when I get the hang of the digital I can make JPEGs

of the bike if RT-340 owners are interested. The other interesting

Rokon I saved is my 1976 ISDT gold medal bike from Austria."

I replied "Your 501 Rokon sounds really interesting. I'd like to see your pictures, I'll put them on the Rokon Web Page." I received this reply. I found it and these pictures furnished by Jim very interesting.

"The

Rokon 501 was a one-off handbuilt machine made by Doug Drussel for the

factory. It was to go into production in 1976

"The

Rokon 501 was a one-off handbuilt machine made by Doug Drussel for the

factory. It was to go into production in 1976

but did not. The "gas tank" shell actually is actually a cover

for a very high air cleaner, and the gas tank is in an aluminum tank

underneath the seat. The rear brake is on the gearbox output

shaft, and the chain slack remains constant throughout the rear

suspension travel since it is on the swingarm pivot axis. The

aluminum torque convertor cover on the left side is hinged on the

front, and pivots outward.

The engine is a Maico 501cc mated to a Sachs 340 lower end, with a motoplat electronic ignition. The photo actually shows a duplicate of the original white fiberglass covering. The original was used to make a two-piece mold, so that duplicates could be made. The original white fiberglass and the mold are also with the machine.

The 501 Rokon was bought at the 1978 factory bankruptcy auction, along

with ten partially built new trailbreakers. The trailbreakers

were missing the wheels, gas tanks, handlebars, etc. and the parts were

purchased from other auction buyers, including the factory Sales Manager

Doug Duncan. The trailbreakers ($140. each) were eventually

completed and sold for

$1000. each which was used to pay for the first Hot Grips® tooling.

Hot Grips® has been in business and is doing well on the internet at

www.hotgrips.com

Without

the ten trailbreakers, millions of heated grips would probably never have

been produced. They have been the original equipment heated grips

on the Yamaha snowmobile line since 1990.

Without

the ten trailbreakers, millions of heated grips would probably never have

been produced. They have been the original equipment heated grips

on the Yamaha snowmobile line since 1990.

Jim Hollander, President

Hot Grips® Mfg. Inc.

I received this e-mail and picture from Michael Cosbar. I'm trying to contact Michael to see if I can get a better picture of this rotary powered bike.

I aquired a Rokon prototype 340 back in 1989. It is one of two rotary powered experimental bikes built in Keene,N.H. The other was powered by a 13 horse sachs, and mine is powered by a 33 horse Sachs motor.As far as anyone knows, the other no longer exists. The build date was sometime in 1974.

It

is basically a 340, with some unusual modifactions. The goose neck angle

has been altered, so the serial number has a weld going through it. It

now reads RT3-08. It has the yellow glass tank and the mag wheels. The

rear brake rotor was spaced off the wheel for some reason, probably to

make the caliper contact better.

It

is basically a 340, with some unusual modifactions. The goose neck angle

has been altered, so the serial number has a weld going through it. It

now reads RT3-08. It has the yellow glass tank and the mag wheels. The

rear brake rotor was spaced off the wheel for some reason, probably to

make the caliper contact better.

There are many parts sourced from other bikes, the fenders are Kawasaki, headlamp is Suzuki, Honda tailamp, BMW muffler, Bettor air forks, clip on street bars, Carlisle flat track tire.

Currently, it is registered and insured, and I ride it regularly. It causes a scene wherever I go, particularly at shows, and Harley bars. (made in USA always works)